Sidestream Analyzer

The ISA sidestream analyzers combine innovative technologies with advanced features to optimize all aspects of gas monitoring. The ISA analyzers are available as stand-alone “plug-in and measure” analyzers.

Recognizing that every clinical application is unique, the intelligent features of the ISA analyzers enable you to extend the clinical application range for your products.

Anesthesia gas monitoring:

- ISA AX+

(CO2, N2O, 5 AA, AA ID)

ETCO2 monitoring:

- Respiration mechanics

- Procedural sedation

- Capnography for ventilator management and weaning <(li>

- Metabolic measurements and nutritional assessment

Automated drug infusion safety

- ISA CO2

(CO2)

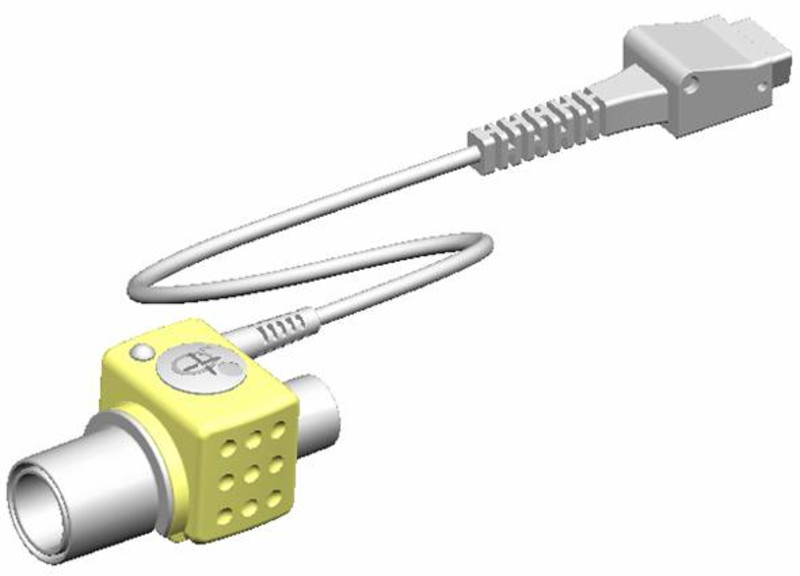

The ISA sidestream modules have, despite their miniature size, all functions needed for a complete multigas analyzer. From the intelligent light emitting gas inlet to an advanced flow controller and a rugged micro pump.

- Low system integration complexity

- Micropower operation

- RS232 or USB interface

- Intelligent light emitting gas inlet

- Interfaces with a paramagnetic or galvanic oxygen sensor

- Utilizes the Nomoline sampling lines

- Integrated flow controller and a micro pump

- 50 ml/min sampling flow for all applications

- Permanently factory calibrated

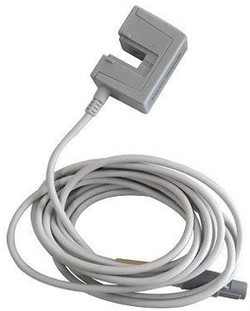

The C500 mainstream ETCO2 sensor is a smart option for ETCO2 measurement. It just needs 3 seconds to warm up. C500 can recognize all kinds of adapters, no matter new or old adapters. Even if the adapter is dewing for moisture, C500 still can get the accurate CO2 values. The C500 is designed specifically for mainstream measurement of CO2 using sophisticated infrared absorption spectroscopy. The measurements are taken at the patient airway at a sampling frequency of 100 Hz, so response is faster and there is less chance of erroneous, artifact data.

Highlights:

- Excellent performance price ratio.

- Better stability: Improved design can wipe off the excursion from temperature, pressure and inconsistent component.

- Response is faster with less chance of erroneous, artifact data.

- No pumping or pneumatic components to be replaced, thus maintenance requirements and overall cost-of-ownership are minimized.

- Long-lasting life for the infrared light receiver.

- Response is faster and there is less chance of erroneous, artifact data.